One of my regular readers, Grant, sent me this design challenge. I have a lot of personal interest in it because I’ve been day dreaming of building a small lightweight tiny house for taking my family (Julia, Katie, and me) on short road trips. It would also make visits to the family farm more comfortable. Here’s what Grant asked for:

I want a structure that will be comfortable for one, contain all amenities (shower, toilet, cooking area with stove and small fridge), be comfortable year round, and here is the real kicker, small and light enough to be towed by a Toyota Corolla (1500lbs capacity). I wonder what kind of creative solutions we could get for something like this.

Initially I’m picturing some sort of pop up, with a foot print of 10 x 6, to allow for a 6×3 bath in the rear, and a 6×7 main room. The main room will be dominated by a table which takes up half the area lengthwise. The bed sits on the table for sleeping, but gets lifted to the roof for storage, revealing a cooking surface. Parts of the table can lift up for under counter storage.

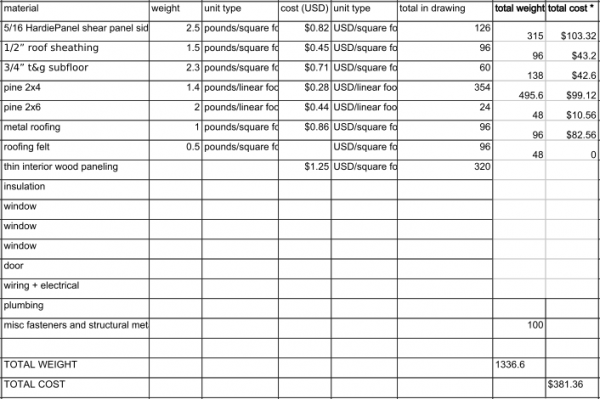

I’m not sure a popup is really doable and might have issues with being weather tight. So I decided to start by investigating what a small traditionally framed house would weigh and quickly discovered that even a house of this size would be much more than 1,5000 pounds. Here’s the simple design and snap shot of the incomplete spreadsheet I started. I stopped doing the math calculations when I realized it was going to weigh much more than 1,500 pounds when you factor in the trailer.

At the moment I think looking into lightweight honeycomb panels, like those used in some variations of the Sonoma Shanty, will be the best way to go.

Another way to go might be to finish out the interior of an enclosed utility trailer. This would make a fairly industrial looking tiny house but it could be a much more aerodynamic and lightweight solution. I don’t really like the utility trailer option because it looses all the positive aesthetic qualities of a tiny house and the retrofit work could theoretically push it way past the weight constraint.

I still think there must be a way to build do-it-yourself lightweight panels from common building materials. So I’ll continue to noodle over this. If you have any suggestions please share them. As spring approaches I bet there are a lot of us that would love to find a simple, low-cost, lightweight way to build our own little tiny house on a trailer.

Thanks for sending me this challenge Grant! I hope we can come up with a solution.

I don’t know the weights involved but maybe metal studs, 1/4″ plywood or 29 ga. sheet metal run horizontally, A shed roof instead of the gable. Sorry I can’t be more helpful, weight considerations were never anything I had to deal with in building.

Some other considerations if this is not meant to be a long term solution: Maybe some sort of tiny house/yurt fusion? Use fabric and insulation for at least part of the structure, similar to what is used in a yurt. Maybe shoot for more of a conestoga/arched roof/vardo look? Also a table that folds down over a bed would be simpler than the reverse and you could easily have cushions come up to access storage.

You will definitely need to go for light weight materials. Love the Toyota Corolla, but towing at the limits is risky (I know, having once towed an ‘82 Toyota Starlet cross country with a ’76 Toyota Celica).

This video should stoke your idea machine; check out the Caravane pliante Esterel Supermatic on Youtube: http://www.youtube.com/watch?v=FJHqhFjvziw&feature=related

Or, consider the Aliner design by Columbia Northwest (look at the toilet/shower combination in the larger models); these folks have perfected temporary living in small space:

http://www.aliner.com/design/Xterior/homepage.php?Type=TEXTLEFT

Think aircraft construction – low profile (reduce wind resistance) and don’t over engineer: consider 2×2 metal studs riveted together (facing each other to form a box) or metal tubing for framing; rigid foam insulated sheathing; plastics (sorry); light weight metals over very thin plywood (thin SIPs); and bolts with lock nuts for fasteners. Possibly obtain appliances/hardware from a salvage yard travel trailer.

If you’re houses get any smaller, just buy some Filson clothes!

I’m confused. Are you redesigning the wheel? Aren’t we talking about a travel trailer now?

Our family once had a 14′ Sprite trailer that could be towed with a 4 cylinder. Sprite smallest now is 17′ and comes in at about 1800lbs but there might still be some good used ones or certainly other manufacturers who still make 13 or 14′ travel trailers.

Structurally, if you want to build your own, you have to stop thinking like building a house with wall framing. You should be looking at space frame made of light weight wood, with a fiberglass or aluminum shell ( Think Morgan sports cars which are still made today with ash frames and aluminum shells)

I would use sheet metal for the siding as well as roofing like the BIG CAMPER MFGs do. Steel is cheaper but heavier (the siding will add to the structural strength of the building). Think 2×2’s and styrofoam for insulation. Wrap everything in plastic to stop drafts on both sides of the walls(you can open a vent to keep moistue down).

Corrigated card board would(seen used as a building material on this site) would be strong, light weight and act as insulation.

I will think some more on this and post later. Time for church.

To answer SteveR, yep pretty much. My only dislike for a traditional travel trailer is that they are as sterile looking on the inside as the outside.

I have never scene a hard walled pop up before, but I believe that is the way to go. Aluminum framing and completely metal exterior would be pretty much required. Solid foam walls would prevent drafts and keep out the cold midwest winters. Once that is decided however, I start the process of how to handle the various systems.

Weight is going to be a double concern, since I want a fairly sizable off grid system as well.

You are very definitely at a point where the line between RV and tiny house gets fuzzy. There is a reason why travel trailers are built the way they are and that has mostly to do with the weight issue. A couple of thoughts come to mind right away though. First of all you should use the frame of the trailer as the floor framing of the tiny house rather than building a new floor frame and floor on top. Secondly you could approximate the performance of SIPS by framing with 2×2 and 1/4″ plywood on both sides. Put the 2×2 framing at the plywood joints and glue in 1-1/2″ thick rigid foam everywhere else. Only add additional framing at places such as around windows and where you might need extra re-enforcement for attaching things. Use glue at all the joints between plywood, framing and foam. I think you could probably use 3/8″ thick rough-sawn plywood for the outside with vertical saw grooves to give a more rustic look it you want. On the other hand if you use 1/4″ plywood you could then add strips of wood for a board and batten look without adding too much weight. Consider shopping for RV windows. They will typically be lighter than for housing. Consider using hollow core doors for interior walls. They are lightweight and fairly strong and stiff. You can get them in various wood varieties too.

I think that some sort of folding arrangement could be developed but to save weight part of the walls when the unit is opened might need to be less rigid. Keep in mind though that rigid insulation is light in weight. Maybe fabric covered rigid foam could be an option worth looking at.

The bottom line though in my opinion is that it will be hard to keep the finished product from looking like a travel trailer just because of the decisions that would have to be made for weight reasons.

Malcolm

There is already a solution on this very site that could be modified for this: Nine Tiny Feet!

Im thinking the alternate design with the on board planter pot could be modified for this. It would meet the weight requirement pretty easily and if this guy is willing to live out of a traveling sub-compact car with a trailer house im sure he could make it work.

Obviously his initial size request is not reasonable. 10×6? Thats just about the footprint of the car itself.

There are several aircraft construction techniques you could consider: Dacron polyester over aluminum tubes (extremely light but poor insulation qualities), aluminum stressed-skin (also light, also has poor insulating qualities), wood stressed-skin (using thin plywood skins to carry some of the loads), or carbon fiber or fiberglass over foam panels. Fiberglass over foam isn’t very green, but it does combine insulating qualities with strength. You’d want some sort of surface treatment, either paint or lightweight siding and roofing material, to protect the epoxy from ultraviolet light.

Great idea, between jobs last year, my girlfriend and I bought a used Four wheel camper that weighs just under 600 lbs total. We have a mini four cylinder Ford Ranger that carries it just fine. We are completely solar powered and off the grid. Our luxuries includes a stirling powered fridge/freezer and a portable hot shower. The only comfort missing is the toilet. It is all aluminum, so no wood rot. The camper is a pop up that slides in the back of your pickup, or you can mount them on a trailer to tow. Where can I send you pics? -joel

I would be very interested in seeing the pics of the lightweight unit you and your girlfriend purchased.

We need Micheal to come back from his vacation and liven the conversation back up. I too would like to see pics of Joel Hudson’s camper.

Actually first my daughter, then me and my wife got the flu. I’ll be back at it soon 🙂

Definite drawbacks to having a family, pluses usually more than make up for it. Hope all get better soon and you don’t get hit by the feedback loop. That’s never fun.

The company that builds these lightweight campers is http://www.fourwheelcamper.com

Wrong link…

Light weight would be 4 inch foam panels with fiberglass panels.Fiberglass panels,such as used for a greenhouse. This is what I came up with b/c I am an old woman with no strenght. reason I am thinking foam,light weight.heaft would be in floor and roof,frame. Is this feasiable?

Great minds work alike, I now see this idea of foam panels has all ready been submitted. Next question, how about pvc pipes as framework? I see alot of projects for home items using PVC-can anyone tell me if this is possible, or the problems that this wouldn’t work. Trying to keep cost low is one priority

Great work (as always) Michael- I posted it on my blog- and just checked the shedworking competition (via a link of yours- thanks!), that I might put an entry into. Keep it up! 🙂

-Deek

http://www.relaxshacks.com

And TINY YELLOW HOUSE TV (on youtube) has three more episodes in the works with shoots in March and April. I’ll be letting you know

sorry about that link, too many javas! Try this;

http://www.fourwheelcampers.com/

sorry about that link, too many javas! Try this;

http://www.fourwheelcampers.com/ Here is a llnk to my camper;

http://www.wanderthewest.com/forum/index.php?/gallery/image/1041-buttermilks-ca/

Pretty interesting. Can someone please explain to me how you export your sketch up images to a website, blog, etc.?

Exporting images from SketchUp easy. Just go to File > Export > 2D Graphic

What are we building a tank?My home trailer build with 1×1 & 2×2 70 feet x 10 feet. Tiny house 8×18 building ultralight out side wall 3/8″ – 4’X8′ T1-11 in sid wall Maple Plywood (Common: 1/4-in x 4-ft x 8-ft 2×4 wall you could make Engineered wood floor trusses I-joist 1×1 with 1/4 Plywood or 1-in x 4-in wood

How about using structural panels similar to gas station canopies or structural insulated snap together panels used in sunrooms.

I am curious if you completed the project, what method you used, and what weight you arrived at.

I’m also curious since I’m looking at a Jeep Wrangler option and the towing weight is 3500lbs

I don’t understand why if we can built a tiny house, and we can build a travel trailer, why can’t we make a travel trailer thatismore like a house or vice versa?