A House for Khayelitsha – Update

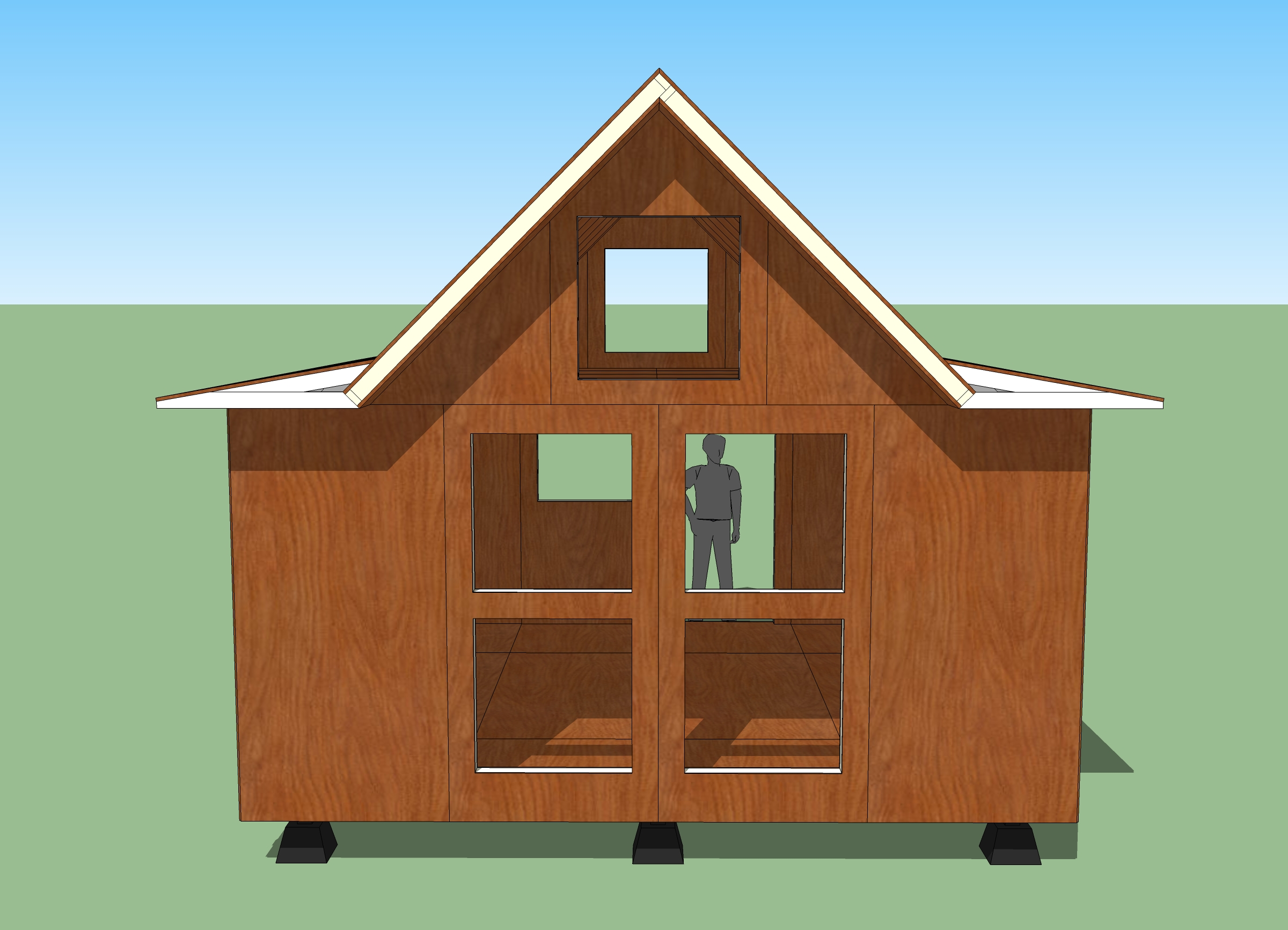

I’ve been working on this 16′ by 16′ design every night this week and wanted to share an update with you. I’ve worked out most of the prefab panel construction details and how they all fit together. The next step is to work out how best to arrange the interior so that five people (in this specific case, 3 adult women and 2 children) could live here comfortably. The final step will be to publish a set of plans so that someone could actually built it.

One of primary requirements for this house was that it should be easily built, assembled, disassembled, moved, and reassembled by the people who will live here. This is why the design calls for simple handmade prefab panels. The panels could be made out of a variety of different materials but I have it draw with common 2x4s and sheets plywood. The hardest part of drawing a house like this is to work out all the details in the plans so that novice builders could actually built it.

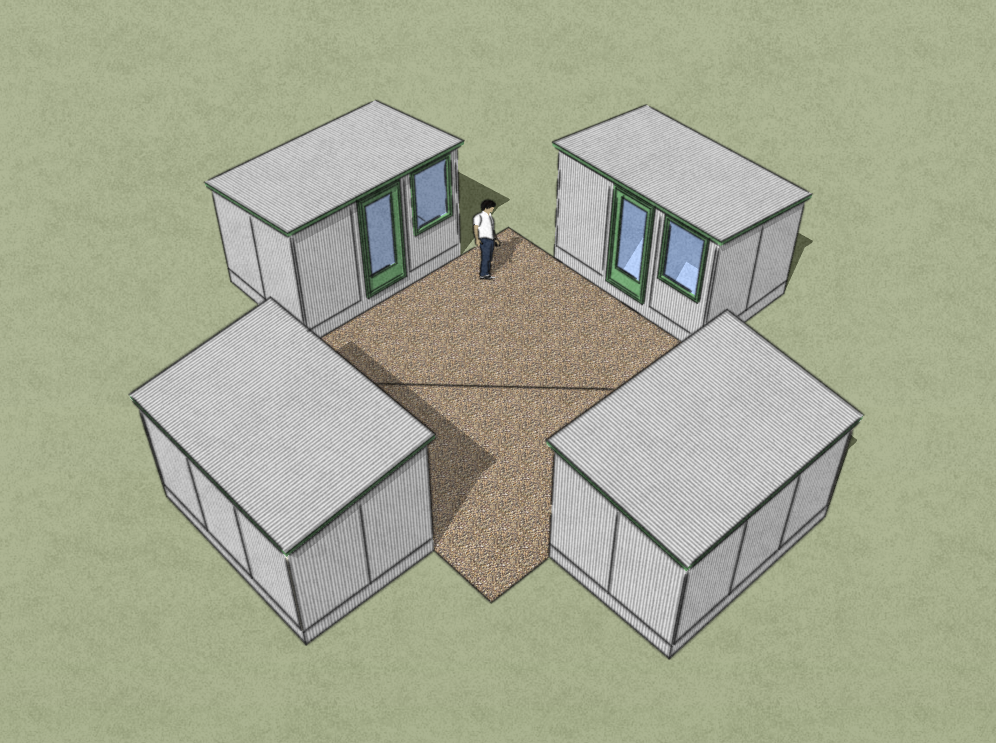

When I’m done with this design I’ll take the same components, rearrange them, and show how a variety of different homes could be built using the same (or similar) parts. I’ll also redraw the Simple Panelized Shelter that got this latest round of design concepts started.

If you missed the back-story on A House For Khayelitsha you can read about the origins of the project at Tiny House Living.

Have you considered using SIPS for the wall and roof construction? They are much lighter than studs, and would make the portability much more viable. They would also offer insulation for the building during hot/cold months that is resistant to mold,insect infestation etc.

Yes in fact I think this would be perfect for SIPs. The problem with SIPs is cost and that it’s not easy to engineer handmade SIPs, so for this project I’m drawing it with 2×4 panels. If you know and easy DIY SIP I’l love to see how that works.

I agree SIP’s panels are the better choice. I am a student doing a project for a company looking into expanding into garden offices/ rooms. Its simply foam in between the panels so I cannot see why expanding foam would not do that same thing. The company makes their own panels as well as buys them in.

Jason

Excited to see the plans. The details of attaching panels (and weather proofing them) is where I keep getting hung up.

Hi Dave… I’ll have those details very soon. Here’s a comment I post this morning on Tiny House Living that explains what I’m thinking on attaching the panels: http://www.tinyhouseliving.com/2009/09/09/homeless/simple-panelized-shelter/comment-page-1/#comment-278

As far as weatherproofing I think the surface plate attachments will work best to keep the weather out.

you may be able to work a deal with one of the sip manufacturers for bulk order(esp when they aren’t getting huge projects recently)

If you’re going with homemade panels (and I like that you are given the project parameters), I would use a diagonal 2×4 to fill the interior instead of a vertical one. I would think that would make the panel as a whole much stronger.

Excellent point Grant. It would make adding insulation a little harder but probably worth it in the long run. Thanks again!

I’m South African. One of the techniques used in low-cost buildings is to use newspaper (well, any old paper!) as insulation. The expensive part is chicken wire to staple over the walls. Make a great big bucketful of papier mache with newspaper, egg boxes, cardboard boxes, and suchlike, with some white glue (the cheapest) or even flour (flour paste was used for sticking wallpaper in the past, but I hate to see food wasted) and then plaster it over the wire. It can be smoothed while damp and painted when dry. There’s an enormous litter problem in South Africa, especially areas like Khayelitsha where there’s no municipal pick-up, so using up waste paper would kill two birds with one stone. It might even allow for entrepeneurship, as the newspaper houses have paper to dump (Junk Mail is a free advertisement newspaper in Pretoria) and then there are the hotels and suchlike that have oodles of paper to get rid of.

Here’s a similar idea: http://multifoilexperiment.blogspot.com/2006/08/12-layers-of-newspaper.html

Great suggestions Suzanne. Thanks!

I’m back – I knew I had this bookmarked somewhere! http://www.treehugger.com/files/2008/03/sumer_erkes_new.php

WOW! Now that is a very cool tiny house. You’ve recharges my interest in insulating my Tiny Free House with newspaper.

I’ll be sure to go look this up again but I think it you spray newspaper with a diluted borax solution it can help keep pests out too. I suspect there are water-proofing trick too. I’ll definitely do some more research.

Thanks Again!

I worked with some other permaculturalists in South Africa and visited some interesting projects, like Thlolego near Rustenburg. I’ve been interested in small low-cost houses for a very long time. I want one of my own!

One thing that can be used for waterproofing is paint. Often a contractor, or a householder, has a small amount of paint left after a project, too little for conventional use. It might be possible for an enterprising person to contact the large firms and offer to dispose of their dribs and drabs free of charge. Mix them all together with due respect for the solvent, and there could be enough for a tiny house.

At Thlolego, cob walls and floors were waterproofed with a mixture of boiled linseed oil and turpentine. This might well work with paper too. The problem again is money. The periurban poor can be very poor indeed.

Here’s Thlolego. http://www.ehow.com/how_4477995_own-milk-paint.html

Another paint I remember reading about is made with sour milk and lime. Here’s a recipe http://www.ehow.com/how_4477995_own-milk-paint.html

Again, sour milk could well be collected free from supermarkets, cutting the cost way down as only small amounts of lime are needed – 1/4 cup lime to 1 gallon milk. Milk paint, according to the following website, is best used internally. It can be waterproofed to some extent for external use with oil. http://www.milkpaint.com/prod_bullet-mp.html I don’t know what that would do in case of fire.

I think though that prevention would be the best – a good roof overhang and a waterproof footing.

Roofs in South Africa are usually metal, on lower cost houses. Corrugated iron for the more upscale houses, flattened paraffin and other large tin cans for the very poor. Tiles are a definite step into the middle class! Corrugated fibreglass can be used, but it’s terribly vulnerable to hail damage. Khayelitsha is on the Highveld, and summer hail storms can be ferocious. I’ve seen hail stones the size of golf balls pelt the world for a good half hour, had my windows broken, and a flock of chickens literally beaten into the ground.

WOW, Great info Suzanne. I’ve never looked into the milk paint option although it sounds familiar. Love the paint recycling idea too.

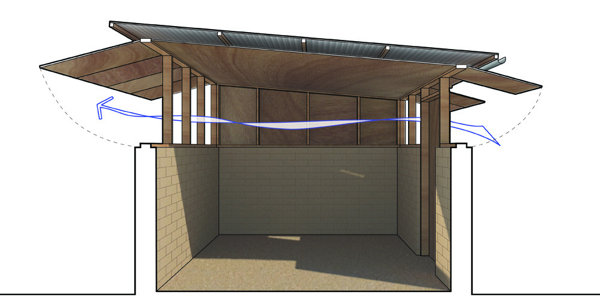

I really appreciate hearing about the weather issue. I had no idea hail storms could be do bad there. I had been noodling over adding top-hinged shutters/shades for the sun-side windows and it sounds like that would be a very good idea. I bet the height of the floor might actually give chickens and other critters a temporary safe place to hide.

Thanks again!

Hi,

I wrote a long post about some other brainwaves I’ve had for the tiny house I hope to build, for your consideration, hit “submit comment” and saw it disappear into a wormhole. I’ll do it again in the morning!

Nice idea but there are some flaws in the basic design when applied to the end user and location.

1) Khayelitsha is a windswept, flat and barren township situated only 3 miles inland in a winter rainfall area. High winds are a regular occurence and winter is both windy and wet. The township is very prone to flooding and is built on saturated sands that inhibits drainage. Whilst hail does sometimes occur it is not of the Highveld type as mentioned by Suzanne, large stones in high concentrations would be a freak event.

2) Shacks (as they are known here in SA) in these low-income (in reality for many; no-income) areas, are high density. The majority of residents use paraffin heaters and stoves (or even open fires inside!) and thus fires occur regularly, sweeping through the camps. Timber is used at the moment purely out of necessity, availability and ease of use. NOT SUITABILITY. Here in South Africa we don’t have an established timber building industry. In fact the majority of our local timber plantations produce Gum (Eucalyptus), Wattle and Pine. These are all fast growing trees In SA and are thus not really suitable for machined timbers. The graded structural timber is often imported and therefore more expensive.

3) The sleeping loft will not find favour with the majority: smoke, heat and other fumes rise. Furthermore there is a cultural resistance to sleeping high above the floor. Everyone will lift the bed off the floor because of the tokolosh [slightly colourful but still reasoned explanation here http://www.vanhunks.com/tokoloshe1.html%5D but anything higher is frowned upon. Unless in a recognised multi storey building of course.

4) Maintenance will never be done, so any materials that require sealing, varnishing, painting, etc. will just be allowed to rot. For many people now living in these townships, there isn’t any history of ownership nor pride in such ownership. Furthermore there will be resistance to what are perceived as ‘poor mans’ houses. For the past fifteen years, the government has embarked on a massive house building programme and has proposed many alternatives to the masonry walled sheeted roof type. None of the alternatives have been well received nor form more than a tiny percentage of those built.

Your design is very elegant but is not a practical solution to Khayelitsha’s problems. All in my opinion of course.

What is the answer? If I knew I would have implemented it years ago.

South Africa is a land of contrast and anomalies and hope. I wouldn’t want to live anywhere else 🙂

Thanks Martyn! The more I learn about Khayelitsha the more I understand the levels of complexity.

The design, materials, and size were the result of a request and set of base requirements. I just finished the final design and will now send off a free copy of the Tint Prefab ebook to the folks that asked for this design. I have no idea if it will be built or if it will really meet their needs. I hope so… but I suspect someone somewhere will find this simple panelized building useful.

any chance of getting a copy of your final plans? How please

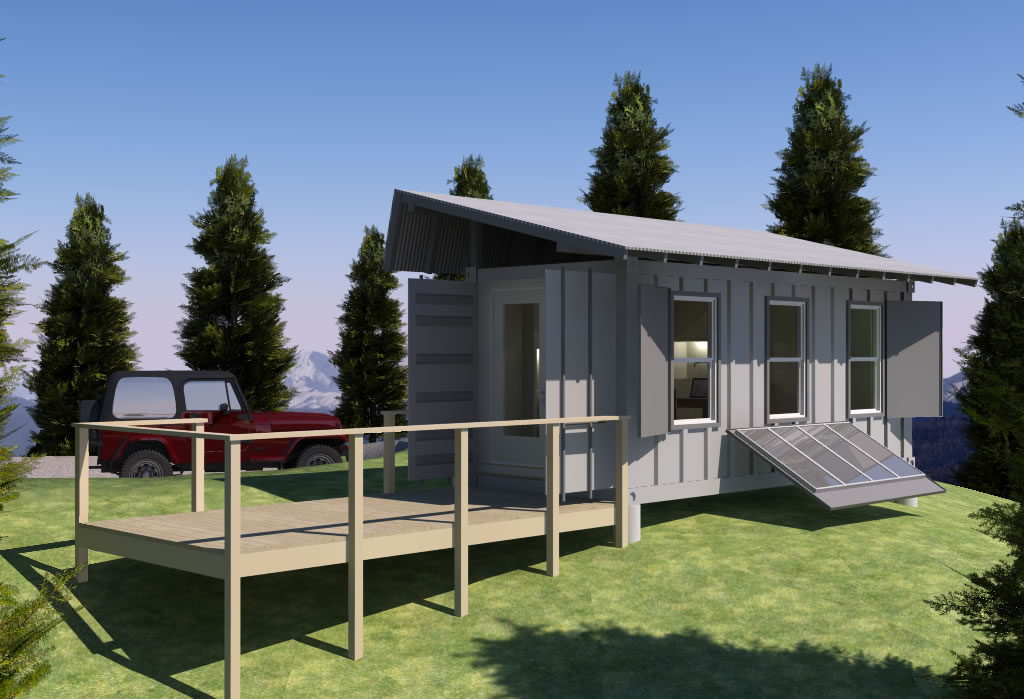

I actually put them in this ebook. The roofline is a bit different because the other one seemed to be lacking some support right where it was needed.

https://tinyhousedesign.com/ebook/tiny-prefab-ebook/

Hi, Michael!

I love the idea of a prefab house. I have little to no room to work with tools in my current place, but I’m hoping to expand my yard when we move next year.

Do you have plans for a single sloping shed style roof for the prefab style house? I was thinking about trying my hand at solar power if my structure is good enough (I’m very new to building, though I’ve made a yurt and some simple camp furniture before). I would love to get as much south facing roof as possible.

Thanks for all of the work you do with these tiny houses!