How to fix a Rocket Stove

Brian (a.k.a Ziggy) recently reported on his blog that his rocket stove is not working. This is a handmade masonry heater he built by hand from cob, firebrick, and steel. It’s a very clever design that has the flu flowing through the cob bed platform. The problem is that it doesn’t draw unless there is a bit of a wind outside. His cob house is located at the Dancing Rabbit Ecovillage.

I took a careful look at all of Brian’s photos and pulled all my old kiln building notes & memories out from my past as a potter and came up with a modification to his design. I’m not sure he’s game to give it a try, but I suspect it would work better with this modification.

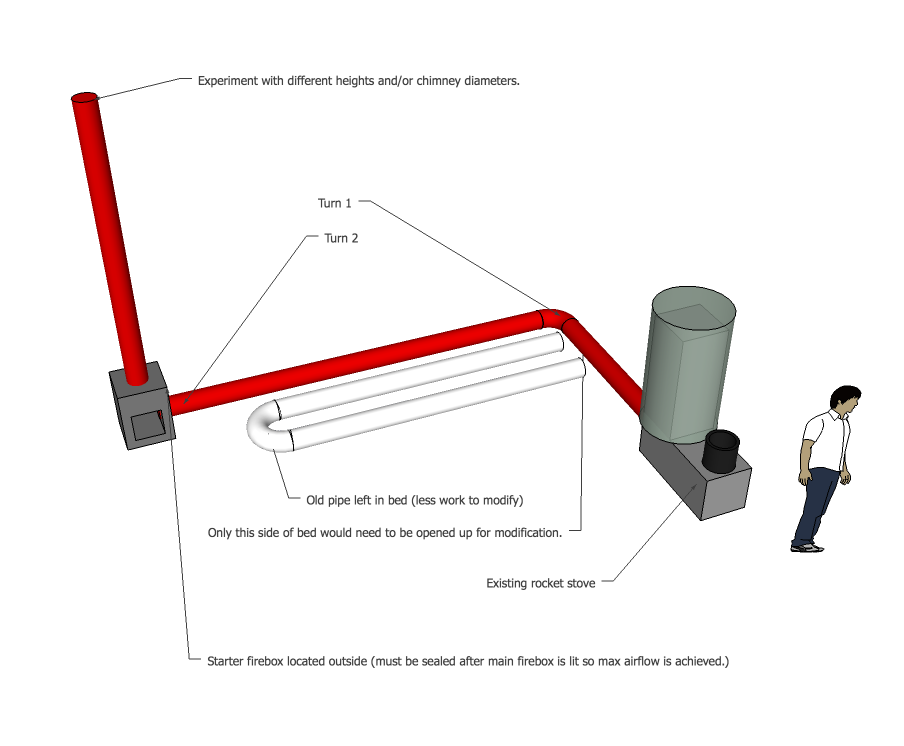

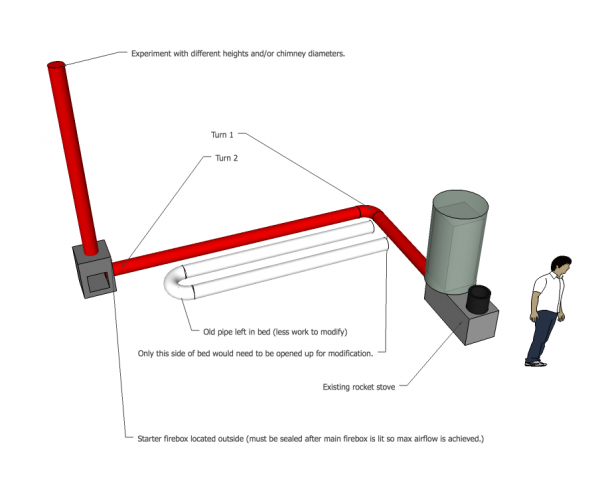

Basically I’m simply suggesting that he digs into the cob a little and connects the stove to the rear exit pipe leaving the other two pipes (white) burried in the cob and disconnected from the system. This would make it much easier for the air to flow because there are fewer turns and less horizontal pipe. My other suggestion is to experiment with a taller chimney.

By shortening the horizontal run of pipe, reducing the number of turns, and increasing height of the stack the ability of this stove to draw air should be greatly improved. The secondary firebox below the vertical stack is optional and would only be used to get the stove going when it’s cold. The only trick with this secondary firebox is that it should be sealed up tight once the main stove is running inside because any air leak in the system would reduce the draw. It’s like sucking on a straw with a hole in it.

In a handmade stove like this, like a handmade kiln, it’s a bit tough to calculate the correct size of everything but if you follow a few general rules of thumb you’ll have more luck.

- Air inlet should be the same size as the air exit.

- Air inlet should bring in air from outside the building. If you draw air from inside you suck hot air from the room.

- The chimney height should theoretically be 3-times the horizontal run but build it to be adjustable so you can tune your custom setup to the optimal proportions.

- Higher elevations require more chimney height due to the thin air and lower pressures.

- Air flow should be unrestricted, so the fewer bends in the flu the better.

- Dampers should be included in the design to help regulate the burn rate.

Rocket stoves have the added challenge of getting the fire up the interior brick chamber and back down inside the metal drum. While this helps transfer heat into the room it’s more kiln-like in that it requires the fire to move through a tall firebox. This will also theoretically require the addition of 3-times the height of the firebox to the chimney. This simply means that this kind of stove needs to have a stronger draw than most stoves, so be prepared to add more pipe to the chimney.

Below are some photos from Brian’s house and rocket stove construction. Brian is considering switching to a small Jøtul stove which is also an excellent idea. I’d love to see his rocket stove working but I won’t knock him at all for pulling it out and replacing it with a high-efficiency stove.

Handmade stoves and masonry heaters, like kilns, are a tricky projects. Professionally manufactured EPA certified stoves are extremely efficient, easy to maintain, and offer low emissions. Before trying a project like this I’d suggest doing a lot of research and even experiment with small outdoor setups like heated benches. The math and physics aren’t that hard to figure out, but when the stoves don’t work and it’s cold outside it sucks when it doesn’t work.

Be sure to visit The Year of Mud: Building a cob house as Brian’s adventure continues.

You can see all Brian’s rocket stove photos and his building a cob house photos on Flickr.

The “rocket” actually generates considerable updraft, if the internal chimney isn’t close enough to the top surface of the drum too much heat will stay in the exhaust and it will not draft internally as well. An exhaust blower could be used to fix the problem too but it would have a small electrical cost.

what about cleaning the tube out? doesnt a build up form inside it?

Couldn’t Brian install a small solar powered exhaust fan on the top of his chimney stack to increase the draw? There are some 12volt units available at marine supply stores that could perhaps work. Worst case he would need a seperate solar panel, a battery and a 12 volt fan. We would not be taking about much wattage required either so the solar panel could be pretty small. I would think this would be a lot cheaper than replacing his rocket stove altogether.

A fan is an excellent idea Malcolm and Emerson. I’ll pass it onto Brian.

Brian, I have a good friend who is really into rocket stoves and knows people~ who may be able to help guide you in the right direction. Below is a direct link to his site permies.com, already searched posts on rocket stoves, for a start. You could post your question/concerns with pics and probably get an answer back quickly. May your rocket stove be revamped & working soon.

http://www.permies.com/

~M

That’s a really interesting idea Emerson. I think it would work fine since the inlet and exit openings are what control how much air can pass through. The hot air would just pass a little slower through the three parallel pipes. Good thinking.

Another thought that occurred to me. If the fan can’t happen for whatever reason and the duct work within the cob must be changed running the three longitudinal ducts in parallel rather than running them in series might help more than cutting two of them out all together and allow the whole bed apparatus to pick up some heat before it is lost to the atmosphere.

Your exhaust pipe should be gently sloping upwards all the way to the chimney. It looks from the pictures that your pipe is sloping down in some spots and I can’t see your chimney on the outside. Your pipe should be at lease 2 feet higher then the highest point of your roof. I saw that you have a clean out under the bed, you may want to burn some news paper to warm up the pipe to create a draft before lighting up the stove.

Good luck

I think centuries of convention regarding chimneys and flues have blinded us to some basic physics regarding rocket stoves. On intakes and exhausts, the intake need NOT be as large as the exhaust as a LOT of gas is added to the circuit by the combustion process. Keeping the air source smaller will help prevent back drafts as any increase in pressure in the combustion chambers will always take the path of least resistance – the larger pipe. Also on intakes and exhausts, I believe great benefit would be observed if the intake air is sourced in very close proximity to the exhaust air. Air movement around (or over) any object (building) creates high and low pressure areas. While the pressure differentials may be thought of as insignificant, consider the effect when surface area is factored into the force equation. An intake in close proximity to the exhaust will minimize pressure differentials. Sourcing the combustion air from close proximity to the flue exhaust obviously will necessitate an external combustion air inlet and sealing of the circuit to prevent the inlet air pressure from being affected by the building internal air pressure.

Another area that I think is mis-considered is designing the flue path through the storage mass. As the gas stream moves through the flue, it constantly becomes cooler, not warmer. As warmer gases rise and cooler gases fall, I believe better draft performance will be realized with a flue sloping downward from the top of the “internal chimney” to the point of gas exit from the flue. I say to the point of exit as heat transfer continues throughout the ENTIRE run of the flue. This means the gases at any point in the flue run, relative to the gases at any other point in the flue run, are ALWAYS COOLER downstream, be it a span of 1 inch or 30 feet. So the flue gases should naturally flow better in a falling flue rather than in a rising flue. I think such a design will considerably reduce the pressure on the secondary combustion chamber or “internal chimney” to push the cooling gases uphill through the flue. No elevation increase in the hot gas circuit should be necessary and, I believe, will actually detract from draft performance, which detracts from the overall performance of the unit. Another advantage of a constantly falling flue is that cold, outside air will have less tendency to flow DOWN into the flue and into the building when the unit is not fired.

If you’re having performance or draft issues, attempt to somehow equalize the ambient air pressures at your flue exhaust and at your combustion air intake. Also, if your intake and exhaust openings are equally sized, reduce the size of the inlet air path at any point to evaluate reduction of backdraft. If you are an engineering type, build a cheap, simple differential pressure water manometer and determine the differential pressures along the entire unit gas circuit (from air intake to the flue exhaust).

Please let me know if you experiment with any of this as I have not proven any of it yet. It just makes sense based on simple physics. I intend to build such a design as soon as I get a round tuit. If you should happen to come across a round tuit before I do, your validation or invalidation of my ideas could save me some time. A lot of frustration with rocket mass heaters cantankerous performance might also be eliminated for many others.

Mike.

Your take on a downward slope to facilitate cooling flue gasses make too much sense. A Basement rocket mass heater application would demand a second riser flue for exterior venting. I am wondering if this will effect any benefit from the initial down slope.

How about introducing an adjustable secondary air intake valve/pipe near the burn chamber which would serve to increase the rocket effect and thus improve the draw capability on the system.

I am new to the concept of the rocket stove and enjoy grappling with the challenge of implementing radically new concepts. I enjoyed Mikes engineering minded comments above. In a typical stove to cool chimney gas temps are a bad thing as gasses condensate and build up deadly creosote which will insulate thermal transfer and cause chimney fires. In a rocket stove the combustion is so complete that creosote should not be a problem. THe concept of a falling cooling chimney is definitely radical in wood burning. The only thing I could compare it to is high efficiency condensating gas furnaces. The exhaust is so cool it runs through PVC and condenses to water vapor. My question is 1. What is left in the flue gas after all the heat is extracted before it leaves the chimney and after it goes through a rocket stove? 2. Does the high heat consume all of the gases including carbon monoxide?

Can the galvanized vent pipe, being used in a chimney application, pose any zinc poisoning threat when it gets hot?

There is no risk of zinc poisoning from a rocker stove – the flue gases are simply to cold.

There are no pics of the chimney height and position on the exterior of the home, as that can often cause poor draw and no starts. A build up of ash in unsuspecting areas too can be problematic in restricting air flow,,, I hope he got it fixed!

Mike has the physics right & really no chimney for “draw” should be necessary after the fire is really going. The whole idea of massive masonry stoves is to burn all the fuel, extract most of the heat & store it in the mass for gentle radiant heating, and have little exhaust left over. Carbon monoxide is the prime danger/challenge with rocket mass heaters. Incomplete combustion as at end of a burn can produce deadly carbon dioxide which is heavier than air and can thus pool inside a living space if not vented from the shelter properly.

The best method of avoiding this is to run the system before burying it in cob.

The most likely problem is the exhaust tube is short for the drum which causes a poor drafting system.

The solution may be as simple as removing the barrel, cutting a few inches off the bottom of it, and doing a test run to see if that corrected the problem.

There may be a problem with a fan – solar powered or otherwise – in the chimney. Even mildly warm air will degrade the lubrication and, naturally, VERY warm – or hot – air may destroy the fan completely.

I learned this lesson with an air heating solar collector system (fortunately, I figured it out BEFORE I even built my collector, let alone before I destroyed my expensive duct fan).

The solution is to put the fan in the INLET side. Of course, that may require some “plumbing” to get it to work right. Consider the venturi method so that the fan is not actually in the air-inlet stream, but the fan air comes into the air path at an angle. (Any auto-mechanic can tell you how a venturi works). The fan should only be necessary to get the air moving during start up. A proper design would allow the natural convection to take over once the chimney is a little warmer than ambient. I’m still looking for a “wind up” fan for my “yet to be built” mass heater, but a simple $2.00 snap switch, like used in a coffee maker (available at Amazon.com, and other places) at the top of the chimney, could serve if using an electric fan. I’d put a normally closed switch – say 75F – in the chimney so the fan will turn off when the chimney is warm enough to draw. Another switch, a normally open wind-up like in public restrooms (available at most hardware stores), in series, would turn the fan off after the system had time to warm up.