After posting the latest design variation for Nine Tiny Feet I got a few requests to make the house more lightweight. This seems like a pretty good idea since that project is really about getting the most value from the least amount of space. Initially I was thinking this only meant square footage but it seems perfectly logical to make it lightweight too. If I could find a way to make it super lightweight nine tiny feet could even be pulled by a bicycle.

But I digress…

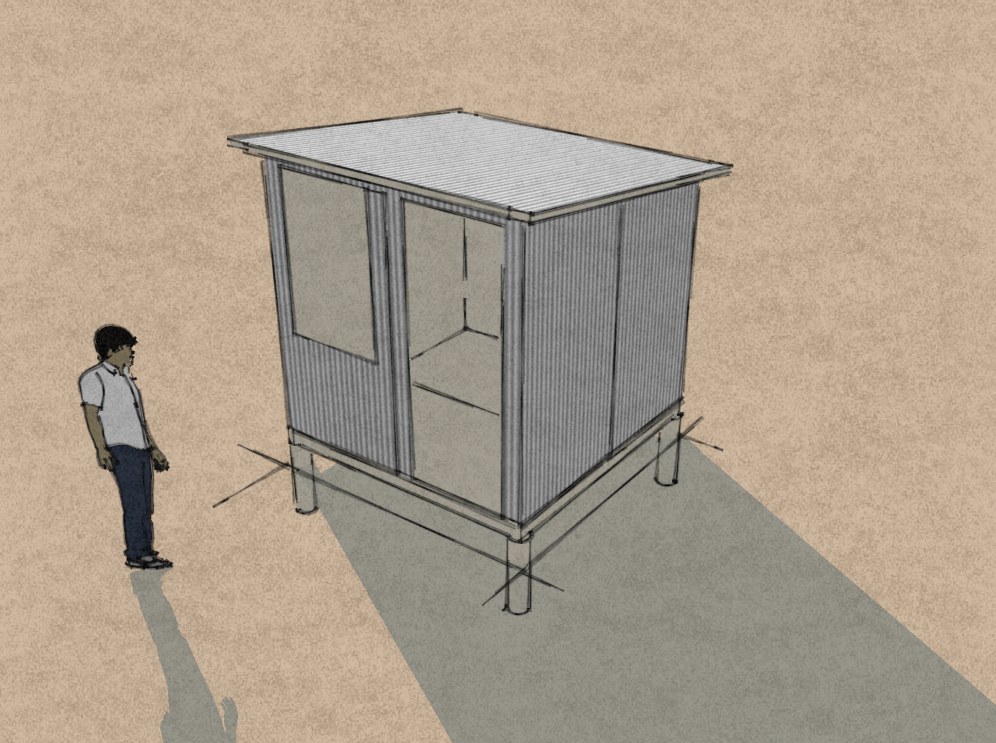

These recent reader comments got my brain cooking up ways of building inexpensive ultra-lightweight panel walls. Then on Sunday night a very simple approach to making panels occurred to me. The design below is not for a nine square foot house, although I’m considering something like this for Nine Tiny Feet too. This design is 49 square feet and could be built for about $1200 in new materials, (less if you’re resourceful and scavenge a little).

In most communities you don’t need a building permit to build a 49 square foot backyard structure so I figured I’d throw the book out and exclude 2×4 framed walls. I’m assuming that the OSB would provide enough support for the lightweight roof and that the metal brackets would hold everything together. But I’m also a bit skeptical.

Is this a house of cards or would a simple structure like this would be sturdy enough for a backyard shed or tiny house?

If you wanted to build a traditional 2×4 framed structure this size and sheath and insulate in the same way you’d need to buy about 40 2x4s at a cost of about $80. If a sturdier structure is more desirable than a lightweight structure then spending the extra money on lumber is probably a good idea. By the same token you may want to use thicker insulation panels.

Below is a drawing of how I imagine the structure being built.

Wall System

OSB + Polyisocyanurate Panel + Aluminum Roofing Panel. Make a sandwich and glue and screw it together. Connect them with a some metal brackets and screws. The only 2x4s in the wall system would wrap around the inside where the roof meets the walls.

It’s also worth pointing our that the OSB is on the inside, then the polyisocyanurate panel, and the metal sheathing on the exterior. Exterior grade plywood and OSB emit fewer toxins.

Floor System

Glue and screw 7 2x4s together into a simple 7′ by 7′ deck. Sheet it with OSB and insulate from below. Put the whole thing on 4 concrete piers.

Roof System

Add four more 2x4s to the top of the walls, and one down the middle, to firm things up and then lay two sheets of OSB on top. Glue two 4×8 sheets of polyisocyanurate to the top of the roof and then screw on some corrugated metal roofing on top of that.

Doors and Windows

When you build the wall panels be sure to leave openings for your door and a window or two. Use some 2x4s to trim out the rough openings. Buy in-stock off-the-shelf windows and doors to save money.

Interior Finish

Paint the walls and ceiling with an environmentally friendly paint. Bright colors will help reduce the amount of additional lighting.

Floor Finish

Seal the floor with an environmentally friendly clear finish to let the wood grain through.

Materials List & Rough Estimate

- 18 8-foot 2x4s – $36

- 12 4×8 sheets of 1/2″ OSB – $108

- 12 4×8 sheets of polyisocyanurate (rigid foam) panel – $168

- 20 sheets of corrugated galvanized steel roofing panels (26″ x 96″) – $360

- 1 window (30″ x 48″) – $100

- 1 exterior door (30″ x 80″) – $200

- 1 gallon of primer – $20

- 1 gallon of paint – $20

- 1 gallon of clear sealer – $30

- 10 tubes of building adhesive – $50

- Screws – $30

- Metal brackets – $30

- Concrete Piers – $12

- 2 joist hangers for the central 2×4 beam – $2

- TOTAL: $1166

Ways to Cut Cost

- Built your own door out of OSB or plywood.

- Find a used window (like on craigslist).

- Use plastic or fiberglass roofing panels instead of steel or aluminum, although these materials will degrade much faster than metal.

Conclusion

I admit this idea is a bit out-there. I’ve seen many different panelized houses but never a do-it-yourself approach like this. I’ll do a little more research to see if anyone has done something like this successfully. If you have any suggestions or know of any good low-cost DIY panel approaches I’d love to hear about it. I bet there are a lot of other people who would like to see a simple low-cost way to build a tiny house too.

Reminds me of this: http://readymade.com/project/gimme_shelter/

Mike, I enjoy everything you’re doing in tiny house design. Have you checked out arialhome.org for their version of insulated (steel, foam, steel) sandwich panels being used in mexico? Thanks for really useful information. gus

Hi Gus,

Yes I’ve seen Arial homes. Great work they are doing. I’ll have to check back and see if they’ve been able to get any traction here in the US. Thanks!

https://tinyhousedesign.com/2008/10/19/arial-home-initiative-prefab-tiny-house/

and

https://tinyhousedesign.com/2008/10/22/arial-homes-continued/

I’m working on an idea for shelters or tiny homes that could be built for the homeless. What I have been working on is structural pieces made from 3/4 inch plywood. The floor system would be the only conventional built part of the house. Walls and roof would be plywood studs and rafters. All the parts could be precut and ready to put together. I am thinking of how light I can make everything this way too.