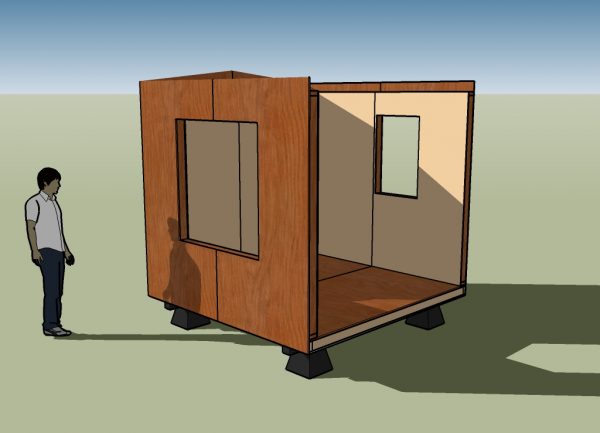

I realize that passionate posts on solving homelessness is a little off topic for Tiny House Design but it’s a topic that seems to need more public support so I figured it was worth venturing into a potentially off-topic area. But now I’d like to bring it back to tiny houses a little more. Below are a few more views of this tiny shelter concept.

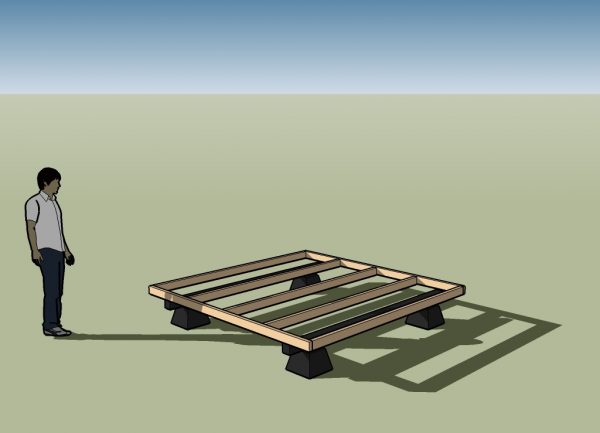

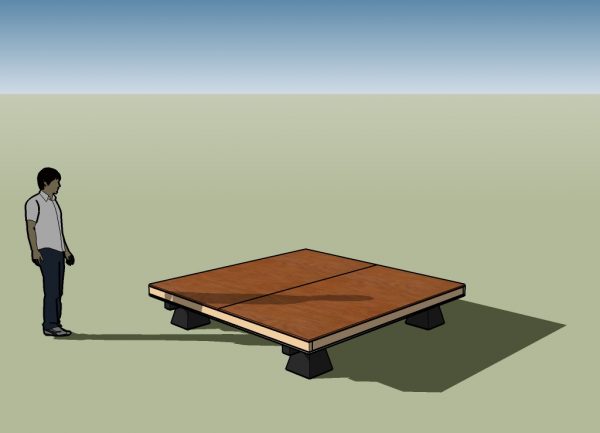

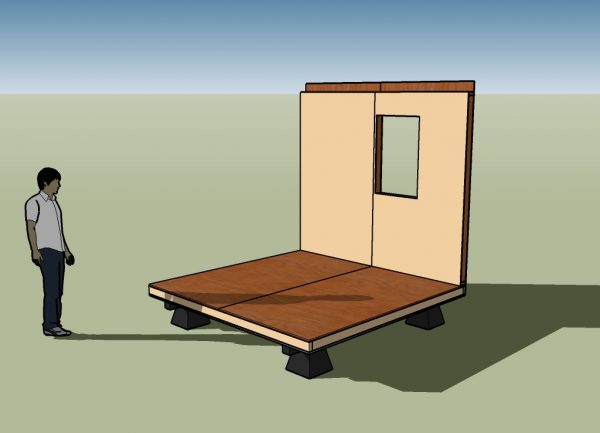

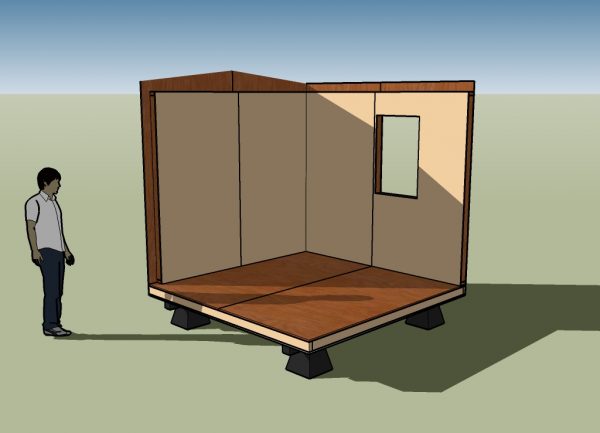

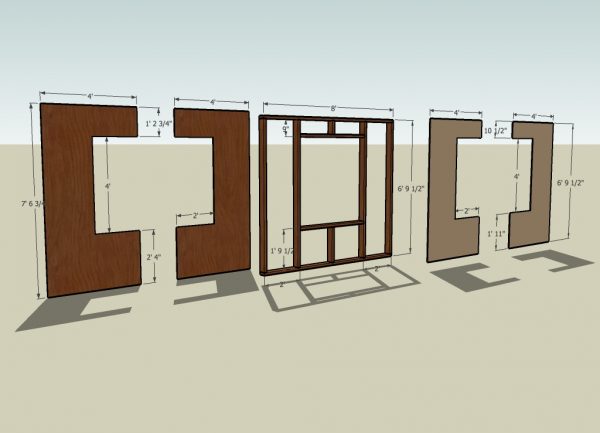

It’s basically six framed panels, floor, roof, and 4 walls. I’ve tried to keep it as simple and sturdy as possible and once the panels were complete they would be bolted together so that it could be disassembled and moved later.

When I’m finished refining the drawing I publish a simple downloadable free plan and a longer print version (plan book) that shows how it’s constructed step by step. While my intention for this kind of simple shelter is for emergencies (including homelessness) it could easily be adapted for a backyard studio, shed, or office. I can even see it serving as a simple remote cabin.

Update: Find the free download here.

My only observation is that the floor joists should be rotated 90 degrees so all of the joists would be resting on the larger beam underneath. It would be stronger than having them attach to a rim joist (which should be doubled by the way).

Great idea and free and sharing is the way to go.

(Old beat-up contractor) Ray

Thanks Ray! Nice to have professional feedback.

Michael,

I like what you had to say about the permitting process. I would also like to try to get more involved in finding such solutions in my part of the country.

Regarding you design you might possibly want to consider making the panels be 4×8 instead of 8×8 for weight reasons and because they could more easily be moved in a pickup truck.

Malcolm

Thanks Malcolm… in fact the refinement I’m working on will use 4×8 panels for exactly the reasons you mention. The only added cost would be a few 2x4s and a tiny bit of weight. I’ll need to swap the 4×4 window out for two narrower windows too.

I’ve been intrigued by the idea of panelized construction for a while. I have an old Popular Mechanics project book from the 70’s that has plans for a panelized “shed” for camping etc. I have always wanted to expand on that with the idea of creating a “real” house, that can be pre-fabbed (say in the back yard where I’m renting), then put together very quickly if I find a suitable lot for purchase (or even a rentable lot?).

I’m drawn to the idea of clusters that could be “connected” or even quickly reconfigured by adding/swapping panels. Obviously quite a few issues to be worked out, but glad to see someone else thinking about panelized construction (and yes – 4×8 is the way to go…).

Thanks Dave. Ironically I’m adapting this design to meet the requirements you just described. I should have the details worked out soon.

Dave – Do you happen to have a scan of that article to share?

Michael,

For your 16′ x 16′ design how are you dealing with the support for the second floor? Without seeing the full framework I can not tell. It seems like the way your layout is setup that you would have to be spanning 16′ with the floor joists of the second level which is pretty far if you are just using 4×4 framing.

How are you dealing with fastening your panels together? They seem to be sheathed on both sides which makes it hard to attach them together with simple bolts unless the sheathing is removable. There are types of fasteners that can be used to attach closed panels together but they would add somewhat more to the costs of the structure than simple bolts would. One fairly simple approach is to use ordinary door hinges at the joints and attach the panels by inserting the pins into the hinges. You have to be pretty careful with the alignment of the hinges when the panels are built though. Please let me know if you want some information about sources of blind fasteners for panels.

Are you anticipating adding insulation to your panels? If these will be used primarily in a hot climate I would suggest that you consider using reflective foil insulation. This should be very effective at blocking radiant energy from the sun. If you are not planning to add insulation then I suggest that you consider leaving off the inner sheathing. This will save money, make the panels lighter for moving and will allow easier assembly with bolts.

Malcolm

Hi Malcolm.

There is a wall down the center to support the ceiling/loft floor. It’s open on the window (solar) side using a built-up post and beam to allow a more open floor plan.

I’m open to any panel attachment ideas. I’ve got 5 methods on mind now that I will include in the plans so the builder can choose. I think one of them is similar to what you’re suggesting (SIP connectors).

It will be insulated. Good thinking on the reflective foil insulation.

Thanks for the good thoughts. It’s really great to have this level of input from the community. More heads are better than one.

could salvaged materiles also used?

Hi Paul… sure I think salvaged material could be used. It just get a little harder to build like I’m learning first hand on the tiny free house (http://www.tinyfreehouse.com)

I found the plans for the shed I mentioned in my previous post online (it was Pop. Sci., not Mechanics…):

http://books.google.com/books?id=BQEMDqBjzHwC&pg=PA84&lpg=PA84&dq=living+cube+lester+walker&source=bl&ots=SmdhO2erOx&sig=_Dx276hFU6WnDhbSIzLkEMcQXDM&hl=en&ei=-DexSp3dF4T8tgfgt_mVCA&sa=X&oi=book_result&ct=result&resnum=1#v=onepage&q=living%20cube%20lester%20walker&f=false

It includes a lot of detail, including materials lists and panel attachment.

Great find Dave… thanks for the link!