Horizontal vs Vertical Exterior Sheathing

Sometimes I like to geek-out on construction philosophy. This is one of those times but fret-not – I’ll make this quick and useful.

Also, I bet there are some contractors out there that just smirked at my use of the word ‘philosophy‘ in reference to construction. But I think it works here because there are so many differing opinions – you’ve got to get philosophical now and then to cut through the chatter.

First, at the end of the day, I don’t think it matters much which way you hang your 4’x8′ sheets of plywood (or OSB – oriented strand board) sheathing on your tiny house.

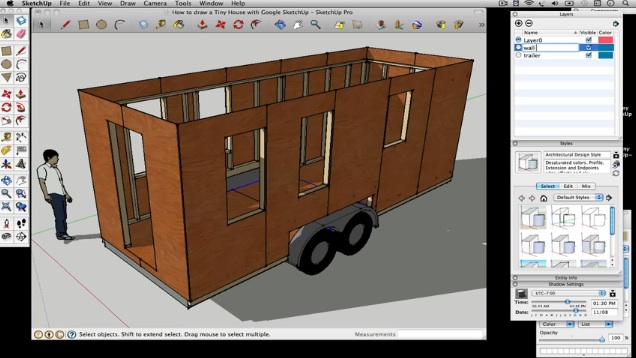

On most houses you hang it horizontally unless you’ve got 9′ sheets that reach from the bottom of the floor framing to wall’s top plate. But when you’re building something small like an 8-foot wide tiny house, it probably makes little difference in structural strength which way you hang your sheathing – just due to the scale of the building.

But lets say you want to maximize the structural strength of your tiny house in every way you can think-up… well the sheathing is the perfect place to start.

Plywood (or OSB) sheathing strengthens your home’s framing like nothing else. It bonds together the framing and helps the walls, floors, and roofs stay square and strait. So it seems logical that the orientation of this building material would play a big role in the strength of the overall structure.

After much research on the matter – as it impacts tiny houses – I’ve landed on a rule-of-thumb to follow:

- If the height of a wall is less than 8-feet, install the plywood (or OSB) vertically.

- If the height of a wall is greater then 8-feet, install the plywood (or OSB) horizontally.

My reasoning is simple. If you can bond together wall framing from the bottom of a floor to the top of a wall, you’re creating a lot of strength. If you can’t span the height of the wall, install it horizontally so you cover more studs along the length of the wall.

But like I said above, I think we’re splitting hairs either way because we’re talking about structure that is just barely over 11-feet tall (not including the trailer) and less than 8-feet wide. In other words, a tiny house is a tight little structure anyway, so orienting the sheathing one way or the other shouldn’t make a lot of difference. It’s a solid little brick.

Floors and Roofs

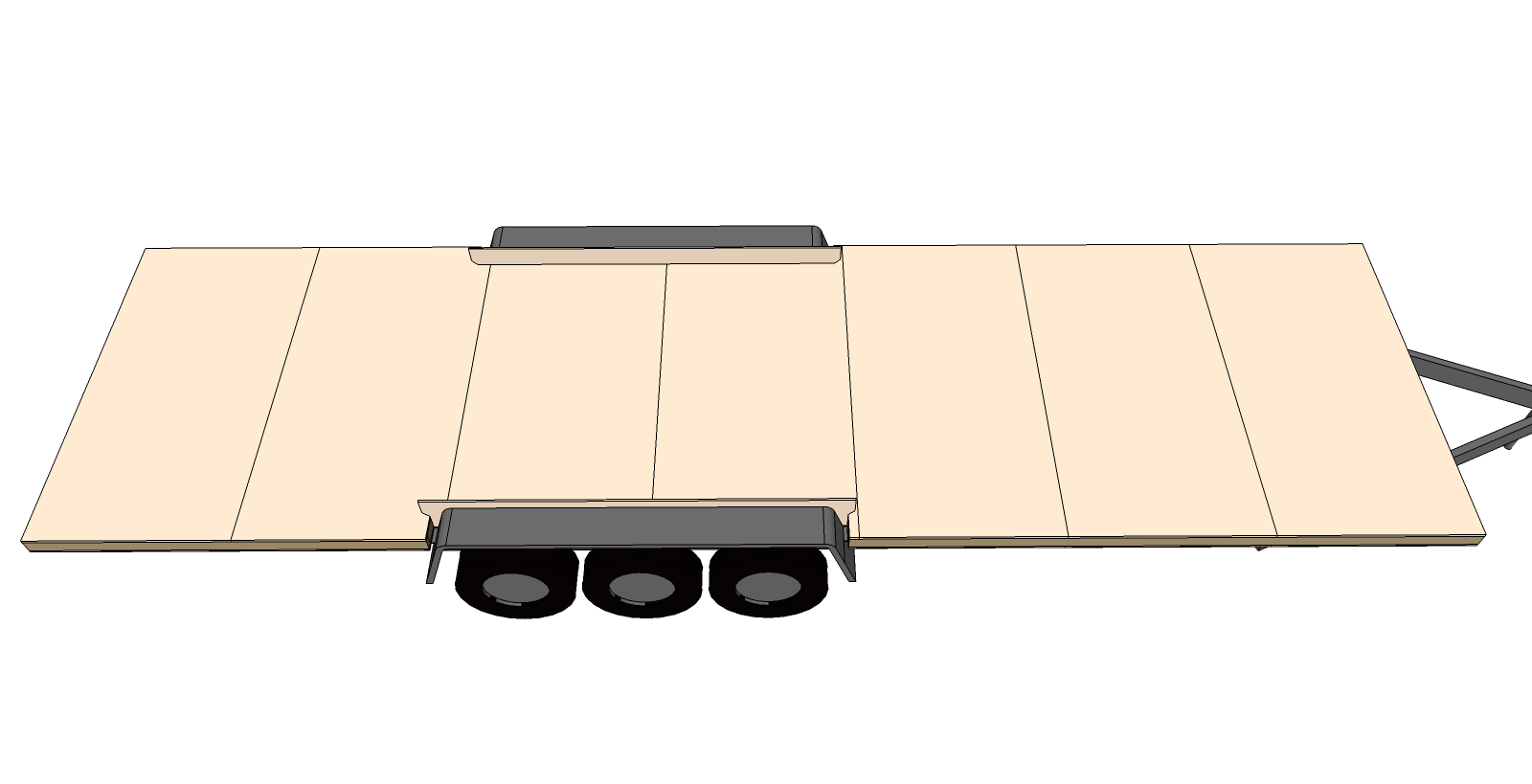

I think the same things goes for the floors and roofs. On the floors in my designs I like to lay the boards across the width of the trailer since it binds together the floor from edge to edge of the house. This approach also means every edge of the sheathing can be secured to the framing. But since the trailer is providing most of the rigidity already – again – you could probably go either way without much difference in structural strength.

On the roof I like to lay the sheets of plywood lengthwise from front to back since that ties together as many rafters as possible with a single 8-foot sheet. Each row of roof sheathing should be staggered so that seams do not line up. This will add even more strength. But remember, anytime you’ve got an unsupported gap, use plywood clips to add that extra bit of strength missing from not being able to fasten to the framing.

Conclusion

So if the wall (plus floor depth) is taller than 8-feet, lay your wall sheathing horizontally. If your walls (plus floor depth) is less than 8-feet go vertically to tie the bottom of the floor framing to the top of the wall framing.

Was this helpful? Did it make sense? Do you have another opinion? Comment below.

Good read, Makes sense to me. Working on a 20′ ocean container cabin myself right now, just getting started with it. I plan on welding in the window frames in this weekend. Making them out of steel tubing. This is just a project I’m tinkering with on the weekends.

Makes sense. Thank you.

Since we’re talking “Philosophically” here, I imagine there is another subtle benefit to installing sheeting vertically. The longer seams between each OSB sheet would run up & down allowing any possible amount of moisture to run off instead of collecting within horizontal seams causing dry-rot over time. I like Geek-Out discussion like this, Keep up the great work here!!

Makes total sense,thanks.

Personally,being a TH Builder,firstly sheet with ply,as it has more structural strength ,OSB has little on edges.One layer ,say 3/8 D/F. Horizontally @ 16 ” centres. Then exterior Finnish ,say Handy Board? A OSB Exterior Finnish Vertical. That way increasing the structural at least 50% more and also increasing the R Value.Prior to insulation.Cost of doing this is relevantly cost effective.Another tip . Use Reflecta foam sheets ,inside.97% reflection of Heat and Cold! works in Satellites. If its good enough for NASA ,need i say any more.50 Ft roll $100.Last hint screw and PL400,no nails. Do it right the first time. Regards a TH Builder.

Seems reasonable, though curiously we’ve done basically the opposite on our build, essentially because we built to code (Australian)

– code only recognises top to floor plate bracing

– code requires floor sheeting layed across joists

– we had skillion roof perfect dimensions for boards going sideways.

I’ve looked at a few different framing situations and there are certainly lots of case by case factors. Lots of wide openings lends itself to horizontal. Internal sheets probably look better vertical in the main. Vertical boards make nogging easier (assuming they span stud heights). I think esse of construction is probably the biggest factor!

I’d be interested in some more specific case studies of where one example makes a significant difference over the other.

As earlier comment mentions, ply inside and out might be a goer too, especially for flexing across the plane of long, high walls with lots of openings (subject to unusual stressors with transport). I have no idea of the calcs or relative merit, but I think about a double sheathed wall in comparison to a SIP wall- it probably has literally twice the direct strength at least as an un braced wall (& immeasurably more rigidity), and in particular will keep the wall rigid wrt twisting, flex at door edges etc (i imagine much more so than standard practice of multiple studs)

I have read your comment,and concur. Here in Canada,codes are very similar .Tiny houses however are not subject ,so far to any major building regulations,i say so far! It is just my personal opinion that a single skin,of exterior is insufficient,for a mobile structure.For that matter a house. SIP,s are an alternative,as you have suggested. But restrictive for TH. due to R factor and space.Especially here in Canada with our weather variance .Minus 30 ,plus 40c. My comment about double skin ,First could be vertical,second Horizontal,50% overlap all falling on 16″ centres .Just made sense to me .As i have done with my TH.Which issuing presented to the Province as alternative housing for low income.My personal feeling is to utilize the benefit of Ply and overlay with OSBin the opposite direction.IE Hardy,or handy board.A cement covers exterior,then coated with Elastomeric . giving a 25 year waterproof coating.Renewable to extend its life. I am of the frame of mind that a TH should last 50 years if constructed correctly.Lets face it TH still costs less than an RV,but affords more,although not so mobile. Regards C.