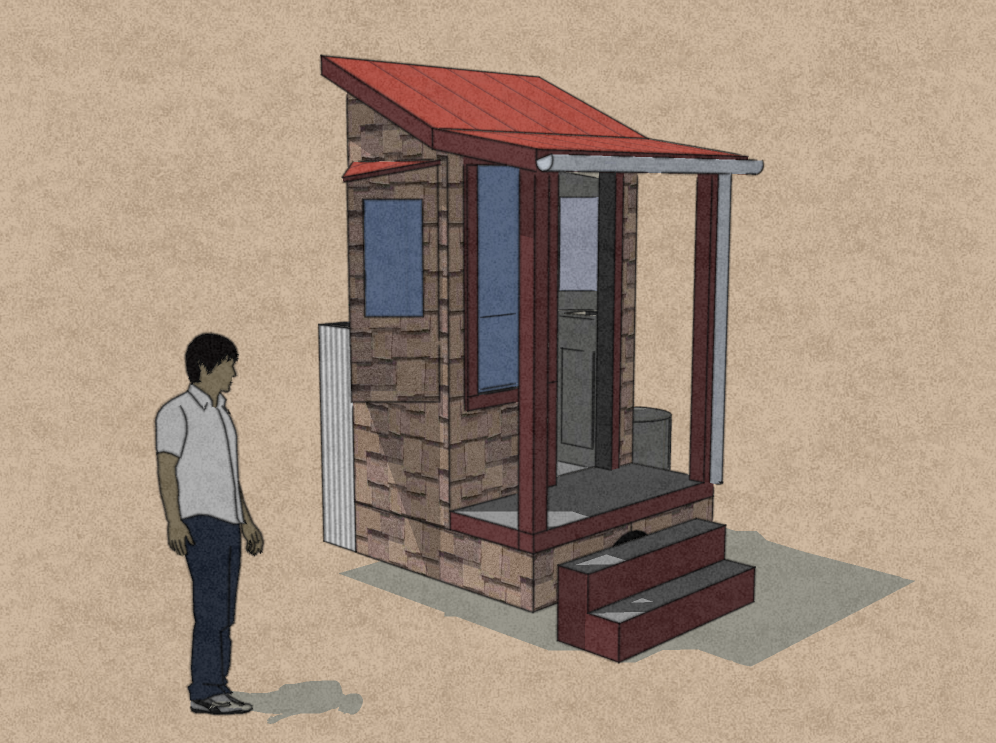

8-Inch Thick Wall Pallet House Concept

A couple weeks ago I posted an alternative concept for a tiny house built from shipping pallets that simply used half pallets (24″ by 40″) as building blocks to form walls. I chose 24-inch walls for that first post because they can be cut from 2-way and 4-way pallets without any waste. It also seemed like a very stable wall thickness requiring little or no additional structure. But 24-inch thick walls also seems like incredible overkill so I went back to the drawing board and came up with an alternative that still uses the pallets fairly efficiently.

As you can see the trouble with building this way when using 4-way pallets is that the forklift fork notches get in the way. In my scavenging I’ve found that 4-way pallets are much more common too. I chose 8″ walls because that’s the approximate distance from the corner of a pallet top the notch. This seems like the most efficient size when cutting into either type pallet.

In this example there are 19 courses of pallet blocks with 14 blocks per course for a total of 266 blocks. Window and door openings would reduce this number so for fun lets just say you’d need 240 blocks. If you had 2-way pallets this would mean you could build these walls with only 40 pallets. If all you could find were 4-way pallets you’d need 80 pallets.

I’m really starting to think that a concrete slab, or similar masonry floor, would be best especially with south facing windows. The 8-inch wall cavity would be stuffed or sprayed full of insulation and could provide a lot of protection from the elements. The roof should be conventionally framed to provide a safe roof overhead. I still imagine the best wall treatment inside and out would be some kind of stucco since it would give character to the imperfections inevitable with pallets.

I’m very tempted to try this idea. What do you think?

The only thing is that with the 24″ walls, your heating/cooling aspects of the house will be greatly reduced. If you use a combination of straw and foam for the filler, then you would have minimal cost for insulation, but save a ton with heating/cooling, even if it is a tiny house.

I’d say if abundant pallets are available go with thicker walls. Vapor proof inside and insulate as much as affordable then if need be temporarily side with housewrap. Add more insulation and permanent siding as permitted. I’ve been thinking of hollow core blocks laid with cores aligned for a warm air heated floor. Saw a house like that in the late 70s. I think it had a thin cement or tile layer on the blocks. Think they were bedded in sand over foam board. A wood vent on each side wall allowed airflow that was convective with solar windows and cathedral ceilings. Seems ideal for small, semi temporary construction.

I’d say the bigger walls would be the schnazit if a feller was to advertize for give-away styrofoam peanuts on Craigslist or Freecycle. Take a couple of the ubiquitous bigboxstore plastic bags, double ’em, fill ’em full of peanuts, tie ’em off, and stuff the walls with ’em. I believe you could heat the place with a candle, and I KNOW you could heat it with an Aladdin lamp. Or if you had electric, one of them $17.00 electric heaters with a blower. Solar panel?

I’m enthused enough to build a couple of these pallet shacks, one using vertical pallets and on using pallet “blocks” (shown here).There’s a 1940’s style camping subdivision near here that has 1/8 acre lots(Waaay too small to build anything conventional on) and I am sure I will make a decision on which to use.

I’m big and bent and grey and old, and the pallet block construction would hold up the sleeping loft for a 300-pounder and his sweetie. Thank the Good Lord she’s not a big’un…

Use one of Old Joe Jenkins’ sawdust toilets and a feller wouldn’t need a septic system(can’t get a permit for one anyway, remember the 1/8 acre?)

I guess you could haul in them big bottles of water for drinking, and the river is right there when a feller needs a bath. I’ve bathed in the creek on and off since 1970, anyway.

Wish I’d a had the nerve to do this IN 1970…

I’ve seen this concept floating around the internet lately. As a Packaging Engineer I can tell you this is not a good idea. The reason being is that wooden pallets are sprayed with harsh chemicals to ward off insects. These chemicals then off-gas over time. This makes pallets a health hazard if used as a building material.

The offgassing is a terrible problem. I believe if you cover the wooden pallets with cob on both sides the offgassing is stopped.

Try using the 12″ parts on the back, or north side, the 10″ pieces on the east and west sides and the 8″ pieces on the front. No waist!

Oh, and put the widows and door on the south side in a cold winter area. that should be the tall side.

I’m sure you guys know a lot more than I do. Have you ever thought of cutting your pallets in half and stand them up right, two full on the out side and a half a full and then a half on the inside, this gives you an eight foot wall with only one cut. I’ve been working and and living part time in a garage, 30″x40″ with 12″ walls and a loft, that cost $38.00 to build in 1962. It now has new steel on the roof and a 40″ lean-to on each side but it’s still the pallet garage I built in 62. Just to note I did scab 2×4 to strengthen the up rights. I know it’s not small but it could be, keep up the good work.

Great pallet idea Bob. Thanks! Love to see photos of the pallet garage too!

OH yes some people call me Sweet Old Bob and some just use the initials .

What about flammability? Especially with the foam peanuts? How do people manage that? And is the cob idea (what are they anyway?), does that really take care of the outgassing? Any other ideas about that? Last question (I think!): Where do you find so many pallets and are they truly free, or just “liberated”? (Ok, so that last question was really two questions, but I tried, lol.)

Hi Leah,

This particular method is theoretical, I’ve not built it. But I think as long as the wall cavity it filled and fire-blocking is in there it would perform similarly to a normal framed wall in a fire. Cob is a mud/straw/sand mix. I don’t think any cob/covering would block off-gassing if that was happening but I think the off-gassing concern isn’t as big of a problem because the stuff they fumigate some pallets with dissipates quickly. That said I would never burn pallet wood because it could release any remaining contaminant. I find pallets mostly at auto body shops, roofing contractors, heating and air shops, motorcycle dealers, and other small business. Large corporate organizations typically hold onto their pallets, the others tend to throw them away because they don’t have to deal with so many and don’t usually have a reuse program. They are truly free… trash. Best to ask permission before dumpster diving.

-Michael

If you painted the interior with an oil based paint, would it block off the gases? And check your local newspaper offices. They usually have ads in the paper to come and take away their old pallets for free.