Home Office and Retreat

Update June 2013 – I never found time in 2011 or 2012 to build this home office. We did adopt Reagan and she’s now 3 1/2. A family member also ran into some health issues – so I ended up building a home office/storage room in part of the garage so I could be within earshot if I was needed. But now things are running smoothly again here at the Janzen household, so I’m back to considering my options for tiny home offices – and updating this design concept and plan.

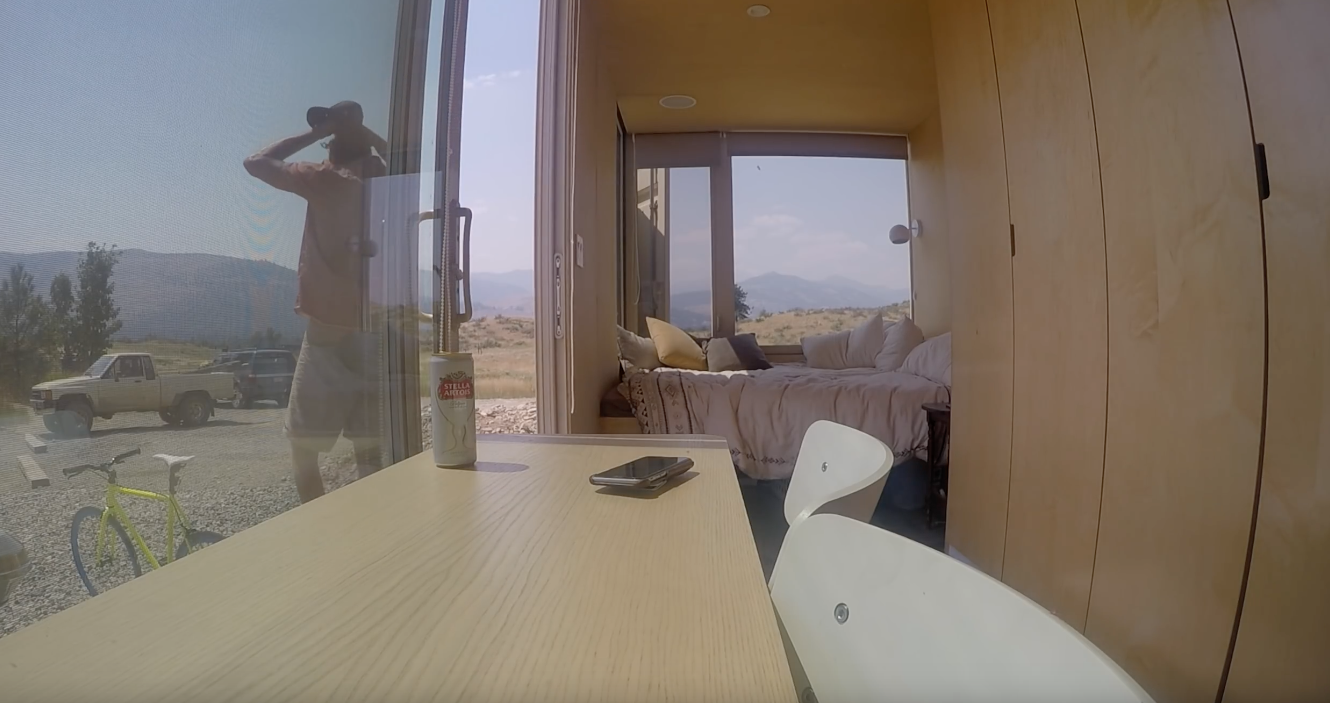

As families grow the need for space changes and tiny house designs like this one might be the perfect fit. I work from home full time and really need a separate office space. I wouldn’t say we need more space – just a space out of the earshot of all the fun. I bet some of you can imagine the challenge of participating on a conference call while the sounds of barking dogs and happy children echo in the background.

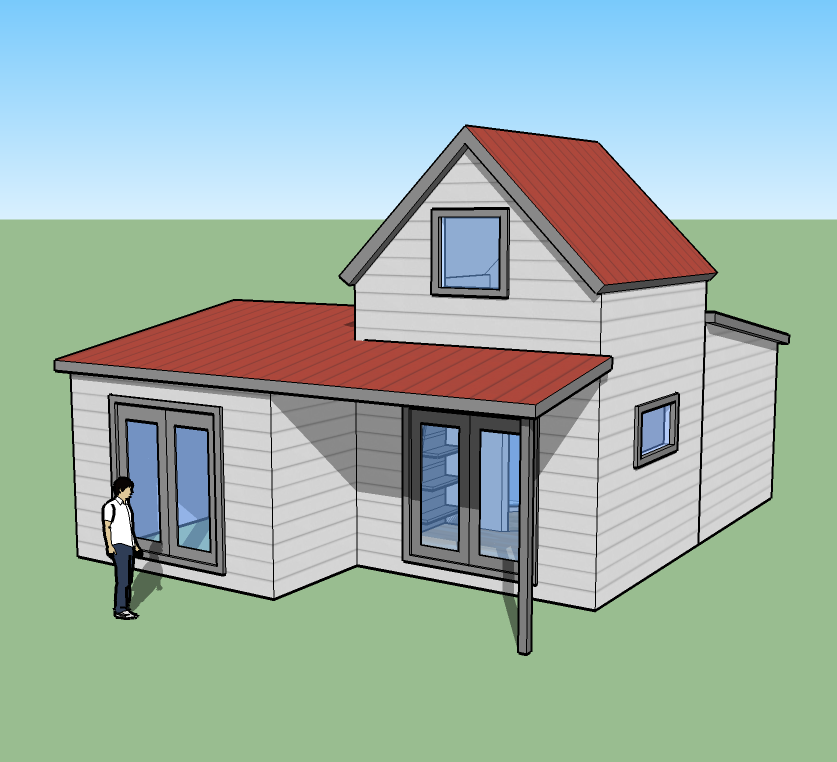

We’ve also been wanting to build a truly portable tiny house for weekend getaways, so this design would serve as both a home office and weekend cabin.

Requirements

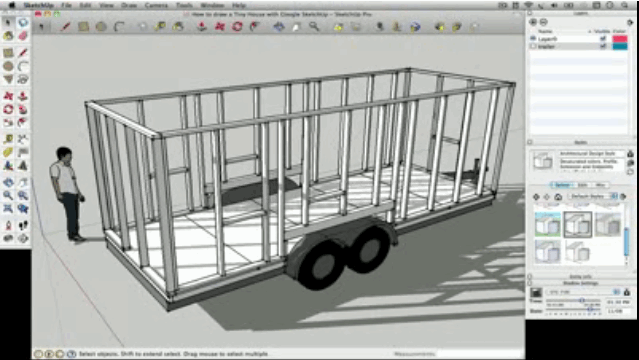

I’ve kept the design simple enough to build quickly on a tight budget. I’m hoping to keep the total cost under $4,000 which will include the cost of a 12-foot dual axle trailer.

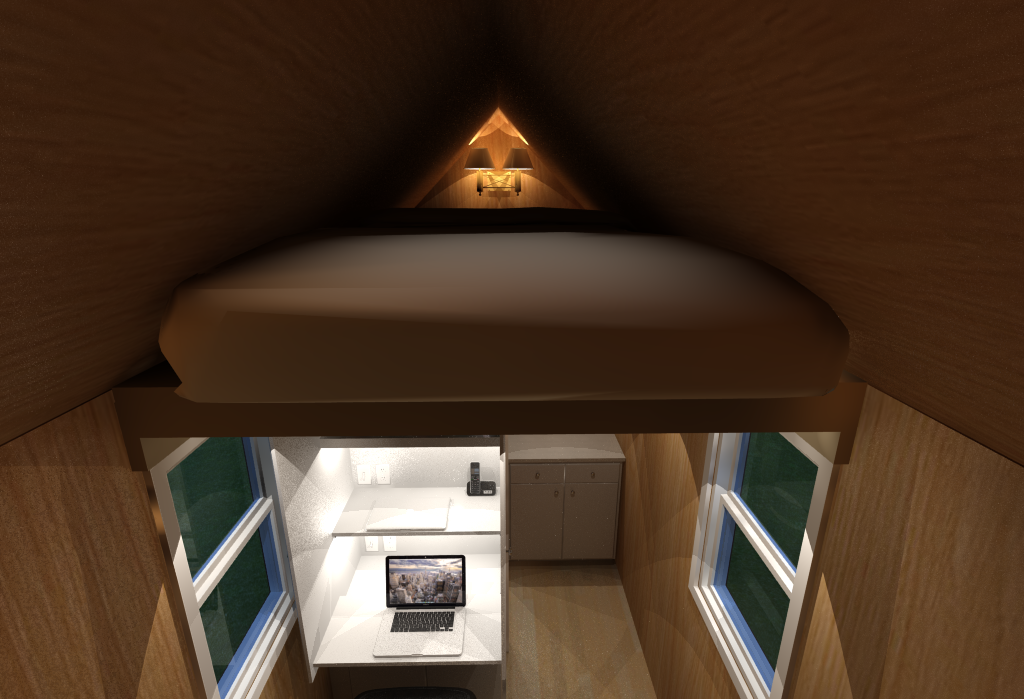

For the office I’d want both a stand-up and sit-down desk to help get me on my feet more. I’ve been working in front of a computer for almost 14 years now and while the pay is good, the sedentary work has affected my health. Now in 2013, I use a stand-up desk now and rarely sit at work – it’s made a vast improvement!

The desk will also need to serve multiple functions when we use the house as a camping cabin. Theoretically a desk should provide flexible workspace and storage. At some point the house will also need to be fitted with a simple bathroom, composting toilet, small food prep space, and sleeping space. The walls and rough plumbing could be built initially and finished later.

In the mean time a water jug and drain bucket could be used in the food prep area. Dee Williams seemed to make this kind of setup work well for her full time tiny house – so it seems like a good way to go for a camping cabin / home office. I don’t think we need a shower.

Construction Method

I think I’d try to use a somewhat untested wall and roof assembly method that will reduce the weight while speeding the construction process. I’d sheath the walls on the exterior and interior with 3/8″ plywood (glued and screwed), but only the interior surface will be installed before the walls go up.

Wiring would be installed from the outside before the insulation, house wrap, and exterior sheathing/siding are installed. I know this is backwards but I think it would work well.

The exterior walls would also be trimmed with battens (ripped from 2x4s) to make the house look like it has a board and batten exterior. I’d finish the exterior with a rich dark stain and the interior with a lighter stain.

The doors and windows would be stock JELD-WEN wood-framed units I can pick up at my local home improvement store. I’d be able to paint the the wood frames complimenting colors to the interior and exterior stains. I could save a few bucks by ordering vinyl windows but I’d be stuck with stock colors.

The roof assembly would be the most unusual assembly and should blow the minds of some professional builders – well that is if it works. I’d lay the interior ceiling plywood onto to top of the walls first, and then installing homemade trusses on top. Then I’ll screw the plywood into the trusses from below, insulate, and finally lift up the exterior sheathing and metal roofing.

I suspect this would make it easier and faster for one person to assemble and keep everything straight since the interior plywood itself would act as a guide. I would not try this method on a larger building, but it seems like a good experiment for this tiny house’s roof.

Project Plan

Prework

- Clear and level space on the side yard.

- Buy trailer.

- Buy building materials.

- Complete rough set of plans.

Stage One

- Frame floor, secure to trailer, insulate, sheath.

- Frame all four walls on the ground nearby.

- Measure and cut the exterior wall plywood.

- Measure and cut the roof trusses and plywood.

- Rip battens from 2x4s.

Stage Two

- Lift walls into place and secure with screws and metal fasteners.

- Assemble the roof and insulate.

- Install the metal roofing.

Stage Three

- Install rough wiring from the exterior.

- Insulate walls, install house wrap and exterior sheathing/siding.

- Install door and windows.

- Finish wiring outlets and switches.

- Bring in a desk, chair, and lamp.

Finish Work

At this point the house will be ready to be used as a home office but will still need finish work that can happen slowly over the following weekends.

- Install interior and exterior trim.

- Install battens.

- Stain exterior and interior.

- Build porch and steps.

- Build loft.

- Build interior walls and add interior bathroom door.

- Install wood flooring and trim.

- Build food prep station, stand-up desk, and bed/bench.

- Add a heater.

- Add a solar electric system.

Next Steps

Update June 2013 – I definitely need a workspace with windows – so will be spending a bit of time noodling through my options and eventually building a tiny house alternative to my man cave (home office) in the garage.

You mentioned the brand of the composting toilet. I’m curious what brand of solar panels and system you’ll be using.

I’ve not landed on a brand, type, or size for the PV system yet.

Great design! Would you be able to share your source for you flatbed trailer? Seems like a really great price. Looking forward to updates as you build. Cheers!

Pac West Trailers is the company here in Sacramento with the low cost trailers. http://www.pacwesttrailers.com/

The national brands all seem to be very expensive and I suspect it’s due to the dealer network. Pac West builds their own trailers so the middle man is cut out. This is just a guess… but seems logical.

If you’re not in Sacramento look for a local trailer builder. I bet you’ll be able to find someone who can build a flatbed trailer for less than the big national brands.

I’m VERY interested in this particular project, since it almost exactly conforms to the constraints my township imposes. (No more than 100 square feet, no more than 10 feet high–They’re even wise to the “build it on a trailer” work-around.) So I’m planning on an 8×12 home office shed.

Since you seem to be anxious to get this one up quickly, and with this “experimental” roof, do you think you might consider doing a video or picture blog? It would be interesting to see how this goes up.

I like the simplicity of your design.

The stand-up computer desk you might be able to squeeze in a stationary bike for exersize. Consider an over-sized seat for comfort.

For your future shower why no an outside one? You won’t be camping in the winter and you can save what space you have and no additional inside work.

http://cheaprvliving.com/howtoconvertavan.html has info on how to make a nice-looking, inexpensive sink from a stainless steel bowl, epoxy, and drain pipe. It would be a natural for this project.

Keep us posted on the building process.

I have an adjustable height desk that works well and saves space.

Thank you for the SketchUp videos – I’ll never be as good as your are but they helped get me started. I made a rough draft and handed it over to my tiny house builder. Very helpful for visualizing.

For your growing family here are two adoption blogs that are well worth reading:

http://www.productionnotreproduction.com/

http://anickelsworthofcommonsense.blogspot.com/

Keep up the good work!

Hi, That is a high price for a 12ft trailer.

Dual axle 7by17 trailer on craigslist in your area

$1600 that is total length,so the actual build approx 14ft.(916)628-7292

Cash talks you could probably get it for much less.

Look for new windows on craigslist.

Lovable loo which you are aware of works as well if not better than the pricey one you mentioned.

Good luck with the build.

And the new addition to your family!!!

Robert

This sounds spectacular. I often fantasize about my future tiny home and one element I keep thinking about that I would like someone to design, is an adjustable height desk that would fold flat on a piano hinge, to the wall, but yet be somehow mounted on two vertical tracks (like some shelving is) so you could raise/lower it and have it hold in place at any level. I do graphic design, writing and sewing, so need to be flexible and think one surface should do it all… as well as a prep site for kitchen work and an eating surface. Any ideas?

Why do you need someone to design this for you? It sounds like you know what you want already, you just need to pay a visit to a few hardware stores to get an idea of the sort of parts that are available to work with.

The “any level part” might be a little harder, but the sort of mechanism used on “quick clamps” and cheap caulk guns might be a starting point.

Go for it – and then post it on your blog or similar to share the results/leave a paper trail for those that come after. But basically I think one just needs to find some good sources of parts and look around to see what is available that can do this for you – there might be something ready to go, or nearly.

Go for it- and then post the project on the web/leave a paper trail so others that come after can use what you did as a stepping stone.

Congratulations on your new daughter!

Your portable office looks great. I alternate sitting at my desk with using a portable computer desk/tray placed on top of my regular desk so that I can work standing. I’m pretty short, so just elevating my laptop on top of the portable computer desk/tray puts it up to a good level to work standing.

It really feels better both physically and mentally to have that option, that’s for certain.

Sheathing the inside first:

Pros – rough electrical cutouts can be exact, don’t have to kneel down to place floor receptacles, corners are easy to thread wire through.

Cons – need ladder to install switches, weather or shelter contingent, any ceiling fixtures difficult to reach (have to get on top of roof?), once the gang boxes are in – have to make trips in and out of house to secure wiring.

Does that cover it? Was there some other reason you figure it would be easier to sheath the inside first? I suppose you could even do the cutouts and install gang boxes before you raised the walls too which could be a significant advantage.

I got a 16 ft trailer from a dealer (Big Tex) for $1300 including tax, title and having pipe top cut off. Same weight as you mentioned (no brakes). Found them through CL.

I’ve only been able to sit for long periods with a kneeling chair. It’s a life saver.

But why does it make sense to skimp on the design like this?

There is a difference between a simple design and an elegant design. And a simple design is not always better. If you are spending $4000 and several hundred hours on it, it doesn’t make sense to skimp on the design phase. Given that you have a blog, what I would do is at least open it up to suggestions too.

I know the suggestions people give out over the internet can be pretty useless sometimes, but they wouldn’t hurt. Maybe you could figure out a clever way to get people to spend some time on their suggestions and get something a little better.

Oops, sorry, I didn’t read the first bit carefully enough, thinking the design was what you rushed out due to lack of time, sorry. I take back the stuff about skimping on the design…

Oh just one more:

People should really stop referring to the nature’s head as a composting toilet. It’s not one.

If you read the humanure handbook you will see this. Not only does no meaningful decomposition occur, it does nothing at all with the urine. It’s only a crap-dehydrating piss-storing toilet.

Wow, now that’s ambitious! Good luck, and congrats on the new addition!

Louis: Big Tex has been the cheapest source of new flatbed utility trailers I’ve found thusfar, too!

This is good news, I can’t wait to see you complete it. The drawings look great and thank you for sharing the files with us.

About how long does something like this take you to complete on SketchUp?

@Louis that’s interesting about the kneeling chair… Did you sell your tiny house yet?

I’m doing a 8 x 16 on a carhauler trailer. Good luck! I thought I would have my floor joist framed up in a day but ran into a few snags…. where’s my screws???? Where did that drill go again??? LOL Hope it works out well. I

@Alex yes, it sold on eBay. We’re arranging shipping to the buyer in CA.

Congratulations on the new addition.

3 days for this seems very ambitious but the important thing is to get started and you have a plan. I would reckon on it taking 2 weeks all put together, given that this is not what you normally do during the day, so it will take some getting used to physically.

Has anyone ever put a rain-screen for the exterior of a tiny house on wheels???? Wondering how it holds up on the road, really like the look of that type of exterior.

Dear Michael

The simple and yet efficient and beautifully-designed cabin is worth every effort. Yet, there is no need to conceive a radical design for the purpose of “working while standing” to be more time “on the move” and therefore more physically active. Standing may be worse. I do train at the gym and can do squats with twice my weight as load and more, do long-distance jog and walk, yet I find it difficult to stand for just a few minutes! No kidding here! To be more active you can replace the chair with a treadmill, gym bike, or periodically step-out of the office and do some jogging. In my office I face problems working while standing because the office floor is lower than that in the public’s waiting room, so I put a high chair to reach the counter. It will be much more rewarding and will save some training time at the gym. Hope you find this helpful.

Thanks Gabriel. Good tips.